Now you can use rapid-prototyping techniques on your personal projects cheaply.

Anyone who builds their own hobby projects is probably familiar with the concept of CNC (computer numerically controlled) rapid-prototyping machines. These machines can build parts, layer by layer, out of a material (usually plastic, but sometimes powdered metal which is later sintered), eventually creating a fully-formed part. Because of the way the parts are built, you can create parts which are physically impossible to manufacture in any other way. These prototyping machines are typically extremely expensive and therefore limited to university labs or commercial ventures who charge outrageous per-hour fees to build parts on their machines.

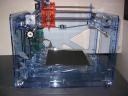

A new open-source project called Fab@Home aims to change all of that. Fab@Home provides you with the plans, parts (if needed) and knowledge to build your own desktop “fabber”. This fabber can be used to build chocolate bars (presumably for fun gifts), silicone parts, project cases, brackets, and pretty much any smallish part you can think of. It’s neat technology that really opens the door to your creativity and with the inexpensive setup that Fab@Home is explaining, it’s in the reach of the kitchen-table inventor or any other hobbyist.

Check-out the Fab@Home wiki for more information. If you’re not familiar with the concept of “printing” objects like that, it might take a bit of effort to understand, but once you do, it’s amazing what can be done!